Web Content Viewer

- ${title}

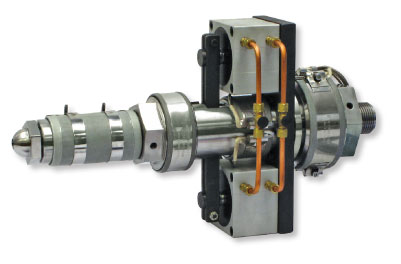

2800 Series Shut-Off Nozzles

For larger machines, 1,000 tons and greater or high flow applications.

Minimum overall length: 12 1/2"

Maximum nozzle tip orifice: 5/8"

Maximum melt pressure: 18,000 psi

Cross-sectional flow area: .442 sq. in.

FA Style

Click here for the 2800 Series Dimensional Drawing

Click here for the 2800 FA Series Dimensional Drawing

When ordering, please specify:

- Make & model of injection machine.

- Adaptor thread length, diameter, & pitch

- Rear opening size

- Nozzle tip radius & orifice

- Thermocouple tapsize (two ¹/8" NPT are standard, one in machine adaptor hex, one in nozzle extension hex)

- Heater band voltage

- Solenoid voltage

- Material being processed

- Injection shot size

- Injection rate(seconds to fill mold)

- Injection pressure

How to Choose the Correct Shut Off Nozzle

Selection of the right Performer nozzle is based on your injection pressure, machine size, flow rate, sled travel and material. Answers to these questions will help determine nozzle selection.

1. What is your plastic melt injection pressure? (Not the hydraulic system pressure)

If under 18,000 psi, any of the Performer series shown can be used. If over 18,000 psi, but less than 30,000 psi, use the 2900 Series.

2. What type of material is being processed?

General purpose materials with no fillers can be processed through any Performer. For materials which are corrosive, have additives, or are shear sensitive, call for more information.

3. Measure to determine which series nozzle will fit your platen.

Note the overall “A” dimension on the drawings. (The minimum OAL can be reduced further by building a combination one-piece machine adaptor and end cap).

S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}