S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Products Dropdown

- ${title}

Web Content Viewer

- ${title}

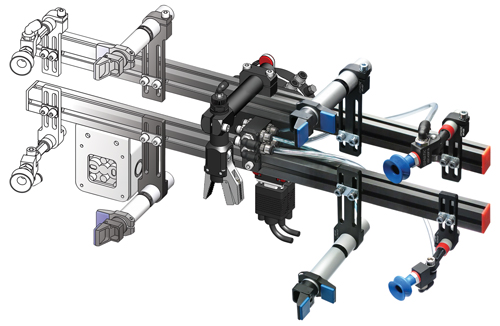

EOAT Design Assistance — No Obligation

Click here to view a 360 degree view of the EOAT

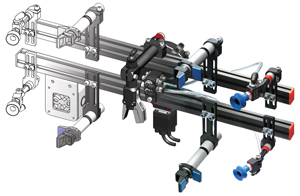

From the simplest to the most complex toolings, our EOAT engineers can design a tooling to suit your specific application. Our extensive stock of framing components engineered for use by injection molders along with the broadest offering of cups, grippers, and everything needed in between, make EMI a one stop destination for robotic end effector / end-of-arm tooling builders.

Need help? Contact one of our specialists by email, or contact a representative in your area.

Have some general questions? See our Frequently Asked Questions page.

Save time and money by having EMI’s EOAT engineers design your end-of-arm tooling at no charge, then build it yourself. You only pay for the parts and there is no obligation to buy them from us.

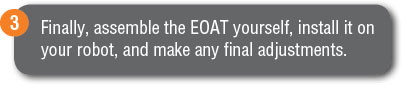

Request a Maintenance Kit for your EOAT Build!

Now available with every EOAT designed by EMI! All you have to do is check the Optional Maintenance Kit box on our EOAT Design Assistance Datasheet and common replacement items will be included with your EOAT.

Commonly requested spare parts include: Vacuum cups, gripper fingers, finger pads, 3D printed components, sensors, fittings, suspensions, and tubing. (Click photo for more info)

You can choose to build the tooling yourself, or you can take advantage of EMI’s EOAT Build Service. Our experienced EOAT engineers and builders will work with you to design and build a precise, reliable tooling to best suit your application.

Note: Your assembled EOAT is tested before it leaves our facility; however, final adjustments may still need to be made once it has been installed on the robot.

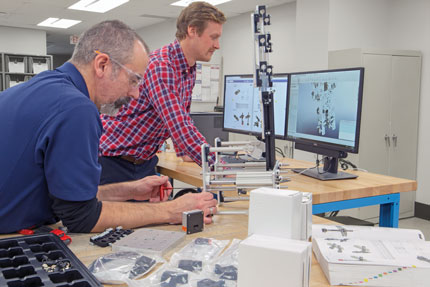

Customer-Focused Engineering - Let's talk EOAT!

EOAT Engineers are available via phone, email, online chat or video call. They will work with you on a degating test, vacuum cup recommendation, cobot kit demo, 3D printed fingers or your next multi-EOAT project set.

EOAT Experts - EMI does EOAT in a big way!

Design assistance is meant to suggest a possible design assembly, so there may be some tweaks or modifications to be made once you have built the tooling. EMI’s in-house Engineering department of 20 EOAT engineers is dedicated to supporting all your needs. No question is too small and no project has been too large.

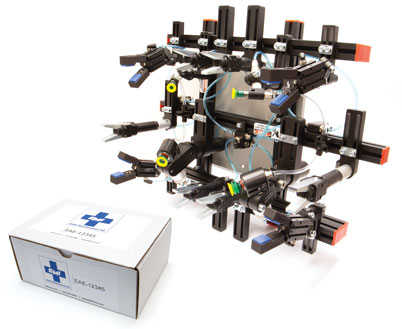

EOAT Build Service - Get skilled assembly by EMI and save time!

Get the benefit of a reliable, professionally built EOAT when you have EMI’s experienced technicians assemble your tool. Many customers find that EMI’s complete design and build service is the most economical solution. Take the assembled EOAT out of the box and install it on your robot.

Advanced 3D Printing for Automation

Since 2013, EMI’s engineers have been utilizing Additive Manufacturing in robotic handling applications for the automotive, medical, consumer goods and plastic injection molding industry. Our EOAT Engineers understand the additive manufacturing process from design to post processing and installation because it is done in-house with quality checks in every step of the way.