S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Products Dropdown

- ${title}

Web Content Viewer

- ${title}

Parts Cooling Conveyors, Water Cooling

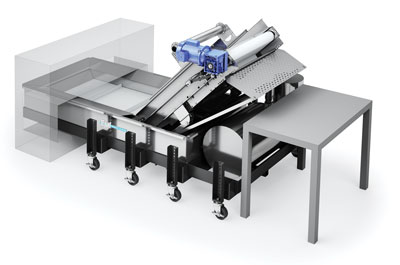

Water cooling conveyors are an excellent way to cool thick-walled parts as they are being transferred to another conveyor or work station. Customized, flat-to-incline conveyors and water holding tanks provide a soft landing and maximum cooling. Units are available in a wide choice of widths and lengths. An indexing option is also available. Tank and conveyor specifications are the same as those listed below for standard Submersible Conveyors.

A wide choice of options allow water cooling conveyors to be customized to suit specific application needs. This Submersible Conveyor, used in conjunction with a robot, has an elevated floor stand that raises it to meet the robot release height. Heavy duty castors allow it to be moved easily within the plant.

Standard Features:

- Conveyor and water tank are fabricated from 12-gauge, #304 stainless steel with 16-gauge slide beds

- Conveyor bearings have cast stainless steel housings

- PVC belting has stainless steel lacing

- Cleats are provided with water drain holes

- A ground fault interrupter is included for safe operation (Customer must provide ground fault protection for 220V or three-phase units)

Cooling the Water Temperature For parts that need maximum cooling, heat exchangers can be mounted to the sides of water bath conveyors to lower the temperature of the water in the water tank.

- 12-gauge, # 304 stainless steel construction

- V-guided, FDA approved, white PVC belt with 1.5" high flexible cleats on 18" centers

- Stainless steel belt lacing

- Side rails lapped over conveyor belt

- Sealed stainless steel bearings in cast stainless steel housings

- 15' power cord with ground fault interrupter plug

- Pre-wired, ready-to-run

- Control wiring contained in liquid-tight conduit and connectors

- 110/60/1 C-faced drive package

- Units under 10' length shipped fully assembled

- Water holding tank may include optional cooling coils

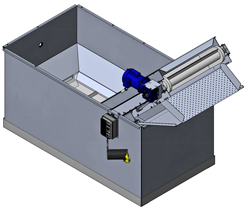

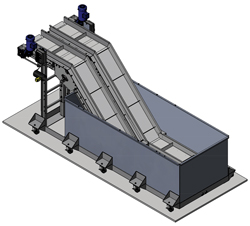

Click images for more detail

Deep Water Baths

This 36 inch deep Wash Tank Conveyor is used to cool parts by immersing them in water.

A stainless steel hopper keeps parts contained. White PVC belting with 1.5" cleats have .25" holes to allow drainage.

Dual Cooling Conveyor Application

Parts drop into the large tank and then are slowly brought up two Stainless Steel KKI Conveyors.

This submersible conveyor has been customized with a containment hopper and mobile floor stand for portability within the plant.

How to Order:

- Send EMI one complete shot of the part(s) and/or runner(s) to be dropped into the water tank/conveyor. Include details on cycle time and how long the “shot” needs to be submersed to achieve sufficient cooling and what water temperature is required.

- Supply a Press Dimensions Form pdf and Conveyor Specification Form pdf indicating length and width of conveyor and discharge height required.

- EMI will recommend a conveyor model and provide a quotation.