S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

Parts Cooling Conveyors, Belt Options

Belting that allows air to circulate freely around and under parts, is an excellent way to promote cooling. Belting can be used alone, or with additional cooling aids such as blown ambient air or chilled air. Choices include Intralox™, flat wire belting or rope belting.

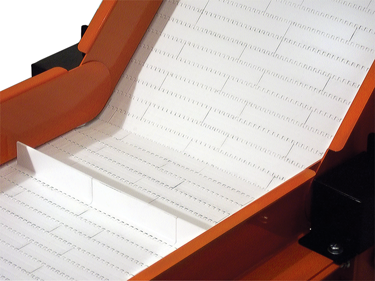

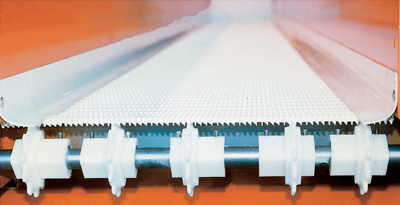

Intralox™ Plastic Belting– conveyor belting (which requires nylon wear strips and a sprocket drive) is easily installed on EMI conveyors. Typical applications include robotic installations and cooling tunnels. Nylon wear strips also promote air circulation underneath the belt. Intralox belting, although more expensive than standard belting, can pay for itself in the long run - if a problem or wear on the belt occurs simply replace a section of the belt.

Click here for a full list of Belting Options

Flat Wire Belting is ideal for moving high temperature molded parts and providing air cooling as they move. Most any EMI flat or inclined conveyor can include the flat wire belting option. (Which requires nylon wear strips). The sprocket drive assures smooth movement. Flat wire belting can be either carbon or stainless steel.

Plastic conveyor belting (which requires nylon wear strips and a sprocket drive) is easily installed on EMI conveyors. Typical applications include robotic installations and cooling tunnels. Nylon wear strips promote air circulation underneath the belt. Plastic belting, although more expensive, can pay for itself in the long run. If a problem or wear on the belt occurs simply replace a section of the belt.

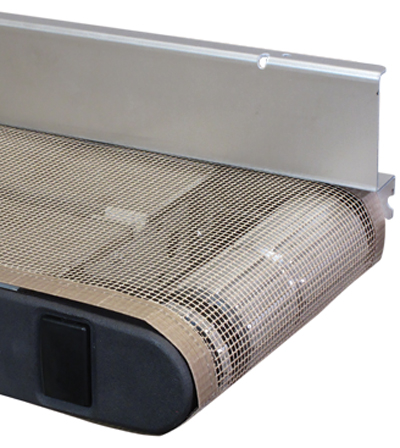

Teflon® Coated Fiberglass Mesh combines the easy release and heat resistance of PTFE with the strength and dimensional stability of fiberglass. Teflon coated fabric is ideally suited for a variety of demanding industrial applications. This option has a max. temperature of 550°F, is non-toxic, and FDA compliant for use in food processing, packaging, and handling. Made from non-woven fiberglass cloth that has been coated with Teflon provides exceptional durability and extremely low elongation.