S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

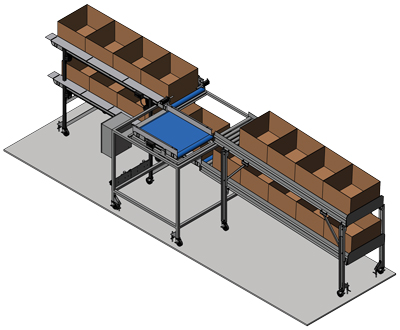

Robotic Indexing Control Conveyor Systems

EMI's indexing controls make it easy to interface a parts take conveyor with your robot.

If your robot does not have its own conveyor indexing program, EMI’s indexing control packages, combined with an EMI conveyor, can provide the same wide range of automation benefits as a robot control package - box packing, stacking, indexing, reversing, orienting, etc.

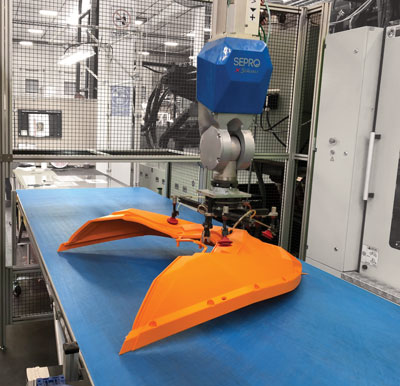

After the injection molding process, parts are transferred to a conveyor by an EMI end or arm tooling where visual or automatic part inspection takes place. The robotic conveyor solutions also offered by EMI integrate end-of-line processes to meet strict quality-control standards.

Indexing for All EMI Conveyor Models

Indexing for All Extruded Aluminum (EA) Conveyor Models

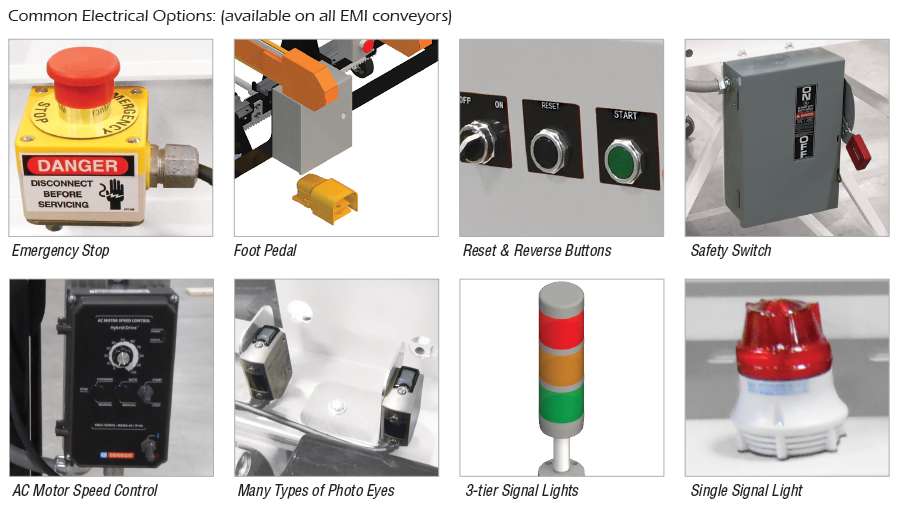

Electrical Indexing Options for All EMI Conveyor Models:

S-44 Indexing Control System:

EMI's Indexing Option (S-44) is a 110/60/1, NEMA 1 electrical control system which indexes a conveyor when a signal is given by the robot. The customer must wire from the robot into the EMI control enclosure a set of normally closed "dry" contacts which open momentarily whenever the conveyor is required to move. This system includes:

- A NEMA 1 enclosure

- A time delay relay - Adjustable timer 1.0 second to 100 hours

- A terminal block used to wire in any of the options listed

- A signal plug with a receptacle used by the customer to supply a set of normally closed contacts from the robot

Adding T-77 DC Variable Speed:

- Allows you to have more parts on the belt to minimize operator time and increase part cooling time

- Provides a “soft” start/stop. Some parts, due to their shape and/or center of gravity, fall over when a constant speed drive starts. EMI's DC and AC variable speed drive starts and stops gradually which prevents this.

Compact PLC Indexing Option for All EA Conveyor Models:

EA-PLC Indexing Option $795:

Available on EA model conveyors, this option eliminates large enclosures normally associated with many indexing packages. The customer must wire from the robot into the EMI control enclosure a set of contacts to signal whenever the conveyor is required to move. This is ideal for robot indexing, box filling, and process control tie-in applications.

- Indexing, reversing, and 6-70FPM variable speed functions.

- Continuous run mode.

- Accepts momentary or maintained signals for indexing and reversing.

- Easily adjustable digital timers.

- English and Spanish language.

- This option is available on all EMI conveyors, contact us for pricing

T-99-VS Index/ Reverse Combination Drive Option:

Available on EA model conveyors, 110/60/1, NEMA 1 electrical control system designed to index a conveyor when a signal is given by the robot. The customer must wire from the robot into the EMI control enclosure a set of contacts to signal whenever the conveyor is required to move.

- Upgrade to a 230/60/3 AC motor and 15' customer interface cord included.

- Smaller footprint on conveyor with no extra enclosures or excessive hardware as needed with S-44 indexing and S-76 reversing options.

- The drive and motor are the only electrical components so there are fewer electrical components to stock or replace.

- An economical choice with less downtime than other indexing / reversing options.

Cobot Ready Conveyors:

Our Extruded Aluminum line of conveyors can be quickly integrated with an Universal Robot.

- Designed to provide continuous part transfer.

- Ideal for pick and place, machine tending, and packaging applications.

- Allows the Cobot and EMI Conveyor to interact without the use of an operator.

- EMI’s URCap is included to easily control the conveyor’s speed and direction.

Go to Cobot Ready Conveyor page.

Polycarbonate Robot Enclosure:

Safety enclosures are a popular option for robotic conveyors. Enclosures can be designed to fit on the conveyor or they can be free standing units such as EMI's popular, pre-fabricated, modular, caging systems.

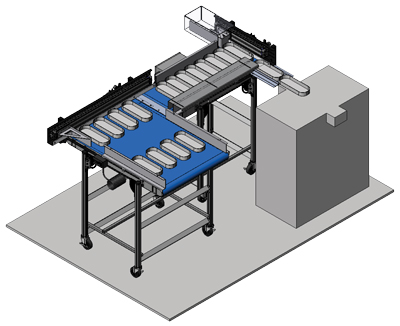

This Extruded Aluminum Conveyor slides out from under the press where parts were placed in box inserts

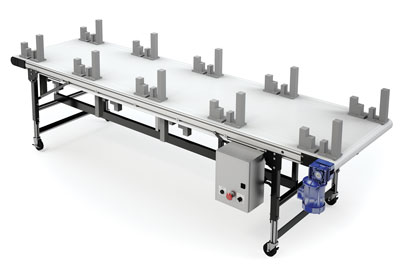

Belting with Nests for Robotic Part Placement

EMI now offers creative solutions when your parts transfers require a specific, repeatable orientation. Product nests, shown here on horizontal belts, can also be customized for inclined applications, to provide effective results beyond what can be achieved using cleats and other methods.

Help keep correct orientation and exact positioning for your additional operations: Contact us to find out if this solution will work for you!