S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

Cycle Count Container Filling Automation Systems

A 'Cycle Count' Container-Filling System is the most economical method to automatically bulk pack small parts into shipping or storage containers. Systems are sized to meet your container and floor space requirements and include EMI standard conveyors and customized control systems which counts molding cycles.

A cycle count system is cost effective and easy to implement—simply enter the number of shots (or molding cycles) to be filled into each container. Cycle count systems can be as basic as the straight inline system shown here—or they can be incorporated many other types of systems including, Over-Under storage, Side-by-Side systems, Tote Dispensers, Turntables, Bag Filling, etc.

Options:

- Delete Cycle Counter (when molding machine is equipped with one)

- “No empty box” alarm and “Alarm Condition” indicator signals no container in next fill station and separate light indicates situation hasn't been corrected

- “Full Box” alarm signals there is no more room for full containers on the holding conveyor

- Strobe lights for either, or both, alarms

- Under the Press Indexing

- Process control tie-in

- Photo Eye to activate a bar code or color code reader

- Pneumatic box pusher to push box off of the trunkline

- Pop up sweep tabs to push boxes back onto the trunkline conveyor

- Sweep arms to move boxes from one conveyor to the other

Cycle Count Control System:

A NEMA 1 enclosure includes a 0-999999 adjustable cycle counter with push button input, liquid crystal display and timer. A cleat sensing limit switch, mounted on the empty box holding conveyor, ensures correct box positioning. Also included: on/off switch, manual reset button, time delay relays and a receptacle with plug, to accept the customer supplied signal.

Simple Installation:

Once the under-press and beside press conveyors are positioned, the control system can be plugged in. The empty box holding conveyor is pre-wired to the control system. The under-press conveyor plugs into the control system. The operator simply programs the control for the selected number of “shots” desired in each container and wires into the control system, a set of normally open contacts that close momentarily every time the mold opens and ejects parts. A receptacle and plug are provided.

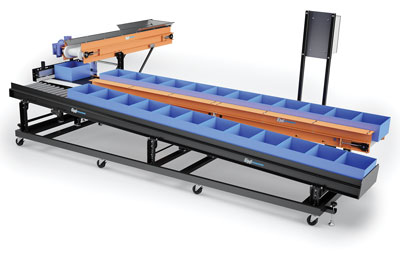

Inline Box Filling

Inline Box-Filling can be configured to meet a wide range of application needs.

Containers can be filled using a machine count, a weigh scale, a weigh scale hopper or a robot. A wide choice of options such as covered cooling chambers, under press hoppers, polycarbonate covers, ionization and more, allow systems to be custom designed to provide maximum productivity.

Shown below, this space saving, single station, Weigh Scale Box Filling systems signals visual and audible warnings when the box is 95% full, giving an operator time to prepare a new empty box. It could also be programmed to signal when it is 100% full.

Side-by-Side Box Filling

Side by side box-filling systems are an excellent way to increase the number of boxes that can fit into a limited space. They are suitable for use with almost any type of fill system including cycle count, Weigh Scale Hopper, robot, etc.

Sweep Arms, can be used for many different types of applications. They are an excellent way to transfer full or empty boxes from one conveyor to another, or to accurately position boxes for robotic filling. A wide range of styles and sizes are available.

How do Side by Side Automation Systems Work?

- Empty boxes are filled onto the first conveyor.

- The first empty box is swept across the conveyor by a 90° sweep arm, to the fill position on the second conveyor.

- When the box is full, it is indexed one position and the next empty box is moved into the fill position.

Side-by-Side Boxfill Application with Belt Driven Live Rollers, Ambient Air Cooling Fans, and Metal Detector.

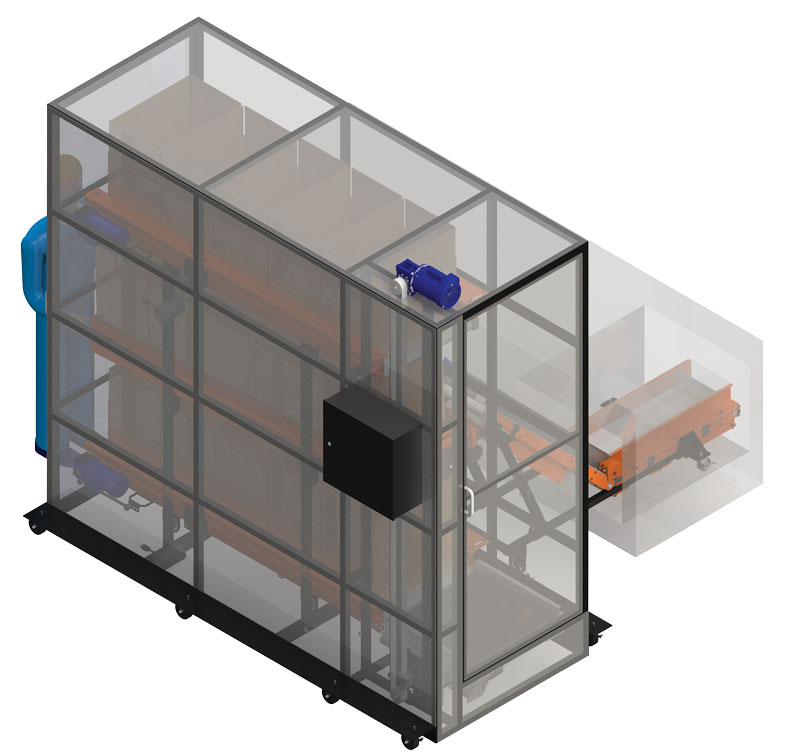

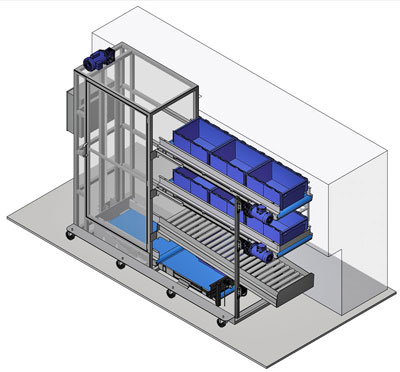

Over-Under Box Filling

Space saving, cost effective, an Over/Under box-filling system provides hours of unattended parts filling. Custom systems can be designed to fit perfectly alongside your molding machine or in any other available space. A wide choice of options allow systems to be custom configured to meet specific application needs.

Basic Over/Under Automated Box-Filling System: This versatile Over/Under box-filling system is an excellent way to maximize your automation dollar.

Maximize automated box-filling capacity in minimum floor space. Large, custom designed, Over/Under Box-Filling Systems are an excellent way to maximize your automation dollar. Systems can be designed to function independently, or as part of a larger plant wide container handling system. They can be sized to fit perfectly alongside your molding machine or within any available area. A wide choice of options allow them to be custom configured to meet specific application needs. Heavy Duty RM Conveyor construction is used.

Side-by-Side / Over/Under Boxfill Application