S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

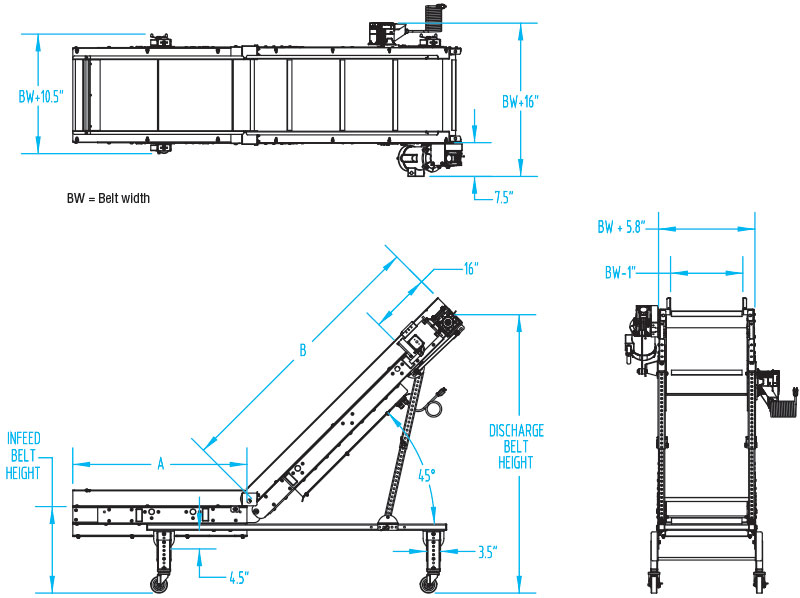

Clean Room Conveyors, Adjustable Angle Model ACRK

An adjustable angle of 20°–45°, makes the ACRK perfect for under the press, along side the press or for moving parts to a trunkline, work station or automatic box filling system. Horizontal to inclined transition rollers eliminate pinch points and assure smooth part transfer. Angles and leg sets are easy to adjust.

Lengths: 5' to 15' in 1ft increments

Widths: 6", 9", 12", 18", 24", 30"

Specifications:

- Anodized aluminum framing and side rails, along with stainless steel guarding and legs resist corrosion and eliminate contamination

- A USDA/FDA approved belting material

- An open-construction slide bed with UHMW contact strips eliminates places where abrasive debris can collect

- Direct Drive motor replaces leak-prone, chain-driven systems

- 1/3 hp 110V input AC Variable Speed Drive

- 4-40 FPM Variable Speed

- Double V-guided, FDA approved, white PVC belt.

- Sealed bearings reduce the possibility of lubricant leaks

- Units up to 10' length ship fully assembled

Available Options:

- Stainless steel framing

- Sealed belt edges to minimize dust from belt fraying

- Non-fraying Intralox plastic belting eliminates friction contamination and is fast and easy to clean

- Wash-down compliant electrics

- USDA/FDA approved Delrin® rail lining to keep parts from touching the metal side rails

- Maintenance-free, grease-lubricated gearbox to prevent leak contamination

- Deionizing blowers to eliminate static electricity and prevent particulates from sticking to molded parts

- Catch trays to prevent particulates from escaping into the environment

Two Ways to Order:

1. Download Conveyor Calculations Sheet pdf

- Fill in the information in sections C and D—as well as any other information pertinent to your application.

- Submit to Sales@EMIcorp.com. For questions call 216-535-4848

2. Call EMI at 216-535-4848 (Mon.–Fri., 8 a.m.–5 p.m., EST) - please have the following information available:

- The conveyor model

- The belt width

- The conveyor length (in feet)

- Belt speed standard 4-40FPM

- The conveyor infeed belt height and the discharge belt height you want.

- Note: Additional widths, lengths, belt speeds, etc. are available.

Standard Models (6", 9", 12", 18" widths) The “A” dimension infeed length minimum is 2.5', maximum 7.5'. The “B” dimension discharge length minimum is 2.5'. A + B cannot exceed 15'. The motor is located at the discharge.

24" & 30" wide Models The “A” dimension infeed length minimum is 2.5', maximum 7.5'. The “B” dimension discharge length minimum is 2.5'. A + B cannot exceed 15'. The motor is located at the infeed.

BW = Belt width

Drive location for 9", 12", and 18" models is mounted on discharge end 11" min. infeed belt height w/standard legs and castors

Horsepower determination charts pdf | Leg location and leg count charts pdf