S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Order Entry

- ${title}

3D Printing for EOAT

Get the custom item you need for your EOAT from EMI.

From 1 part to 100 parts, simple or complex, EMI’s 3D printing service is fast and economical.

Since 2013, EMI’s engineers have been utilizing Additive Manufacturing in robotic handling applications for the automotive, medical, consumer goods and plastic injection molding industry.

As an industry leader in robotic End-of-Arm-Tooling (EOAT), we have found new, innovative ways to approach the traditional EOAT application. From custom nests to advanced hybrid gripper fingers, EMI is continually pushing the limits of 3D printing to support automation in the plastic injection molding industry.

Our EOAT Engineers understand the additive manufacturing process from design to post processing and installation because it is done in-house with quality checks in every step of the way. We have found ways to take additive manufacturing to the next level with complex designs that are used in real world, industrial applications. Find out more about our 3DV for Cobots HERE.

Creating a negative of your molded part to nest and support it has never been this feasible. Isotropic properties allow 3D printed components to act as support and high precision elements in light and heavy duty EOAT applications.

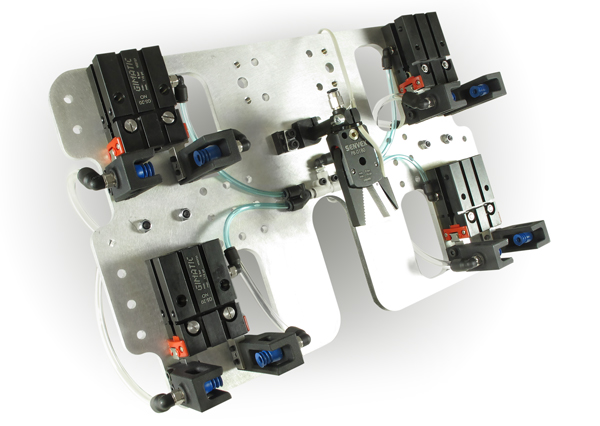

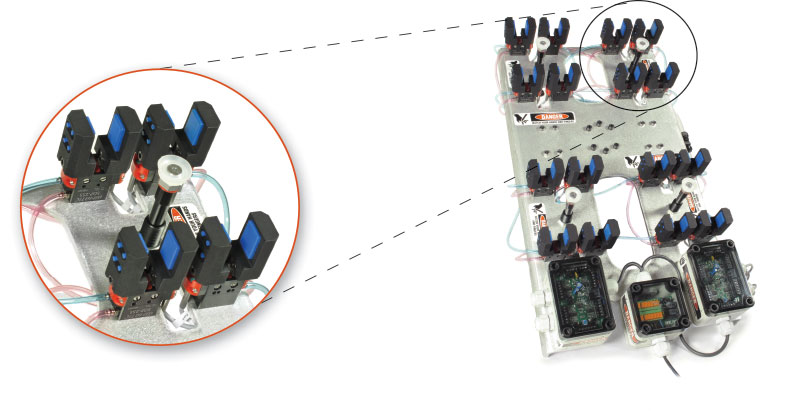

Custom 3D Printed Frame

Our 3D-printed material provides a durable, yet very lightweight mounting interface for vacuum cups, and suspensions in this multi-cavity Cobot application.

Measuring approximately 20in. X 17.5in, this sectional 3D-printed frame is comprised of 5 pieces that are assembled together. It features low-tolerance internal nesting, hardware, and pass-throughs for tubing.

Learn more about our 3D Printed Vacuum EOAT for Cobots.

Click image for more detail

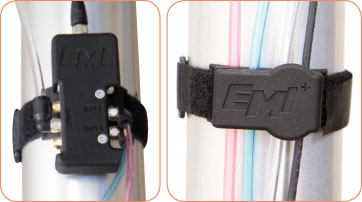

3D Printing for Cobot Accessories

EMI’s Solenoid Valve Kit for Collaborative Robots is an essential add-on for all pneumatic applications. It enables you to actuate Single Acting (NO/NC) and Double Acting end effectors while using a single Digital Output and compressed air line. Organize and secure pneumatic and electric lines running down your robot arm with the 3D printed cable management system

Click here for more information

Vacuum Fingers

Vacuum fingers are a great way to handle your part and detect it without the use of sensors. Talk to our engineers to see if this is right for your application!

Click image for more detail

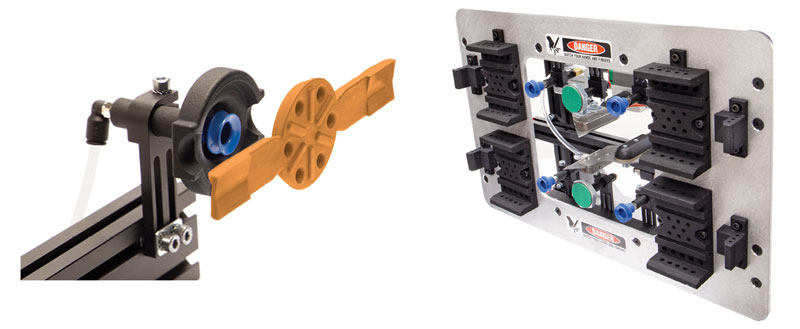

Gripper Fingers

Gripper fingers that would normally be machined out of aluminum can be confidently designed and 3D printed for most applications. Thermal properties vary by material and soft-touch HNBR pads can be added.

Click image for more detail

Components that require very specific geometries can be quickly prototyped using FDM (left finger pictured) and validated before a tool is finished giving ample time for design changes to improve performance. When a final geometry is chosen, the parts can be manufactured (either traditional machining or through additive manufacturing) knowing that they will work perfectly (right finger pictured).

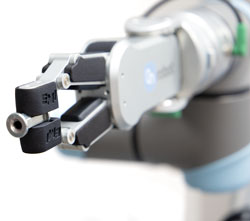

Custom Fingers for OnRobot Grippers

OnRobot’s RG2 & RG6 grippers have a dovetail style finger tip which enables you to use custom fingers made for your application. Easy finger tip replacement allows you to move between jobs quickly.

Click image for more detail

EMI can design and 3d Print custom fingers perfect for insert-loading applications shown to the right, or add flocking for a "light" touch.

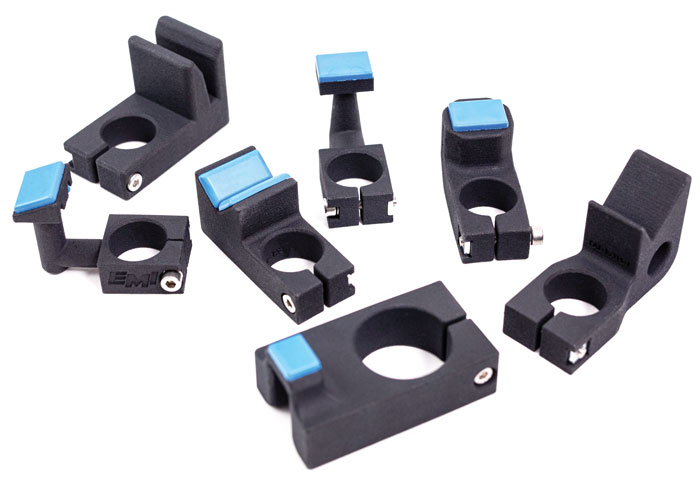

Printed Guides and HNBR Padded Gripper Finger Stops

Custom angled paddle gripper fingers with HNBR are used to support the handling capabilities of Gripper Fingers. Accurately reaching behind a part is achievable with Gripper Fingers, and adding a 3D printed stop offers an even more secure grip. Gripper Fingers with 3D printed stops are a great alternative to handle parts that cannot be gripped with parallel grippers or vacuum cups. Find Gripper Finger Accessories here.

Click image for more detail

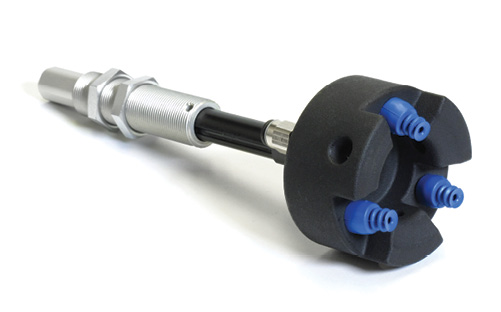

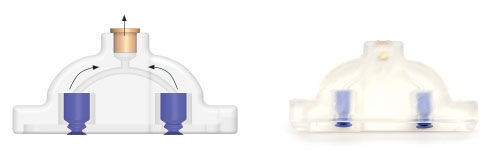

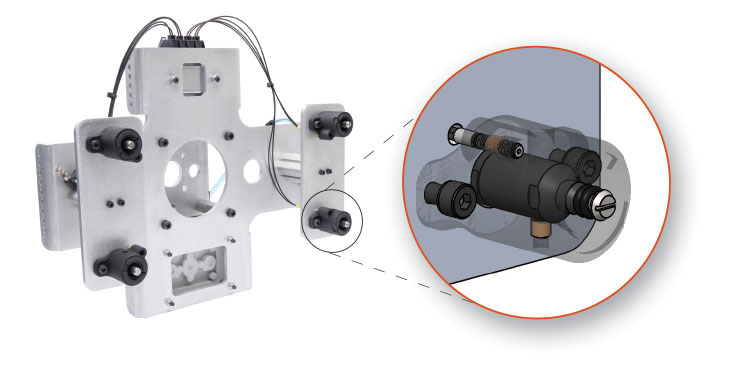

Internal Porting

Create complex internal porting that would otherwise be very costly to machine! Below, a SLA printed vacuum manifold demonstrates how EMI can design & print parts with internal channeling for vacuum systems.

Click images for more detail

SLA Printing Option

Different 3D printing methods can be combined to achieve a level of customization that only EMI can offer. Utilize the AM process and materials to save weight without sacrificing strength. SLA printing (shown below) forms a durable high temp material used for finger pads in a variety of EOAT applications.

Click image for more detail

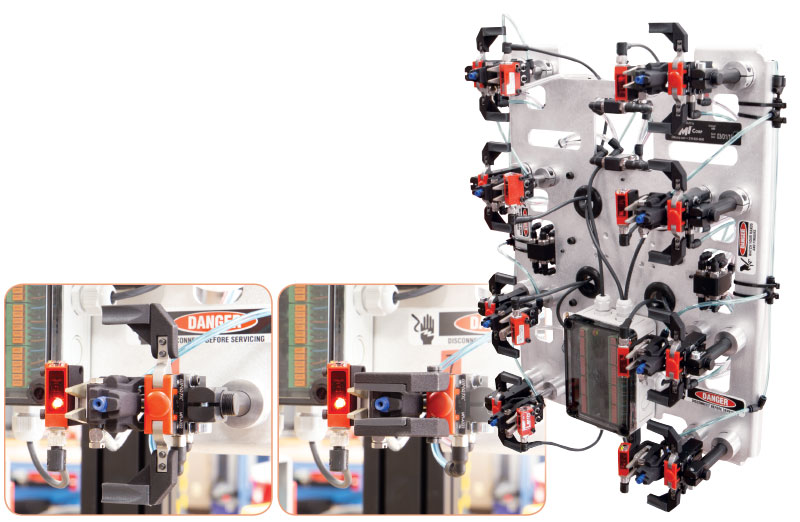

Simplify Tools with Creative Custom Components

Parallel grippers are one of the most common ways to grip molded plastic parts. Using custom padded fingers on a high precision SGP grippers are a great way to secure and detect your part without marring it and minimizing scrap.

This plate-style tooling incorporates fiber optic sensing with an expansion gripper for ID part handling inside of a 3D printed nest. All available from EMI with the help of our EOAT team. See new Fiber-Optic Sensors.

In the application here, a 3D printed nests mounted on suspensions align the part with vacuum for part detection. Once detected, GX radial grippers secure the parts while the robot traverses to drop them on a conveyor.

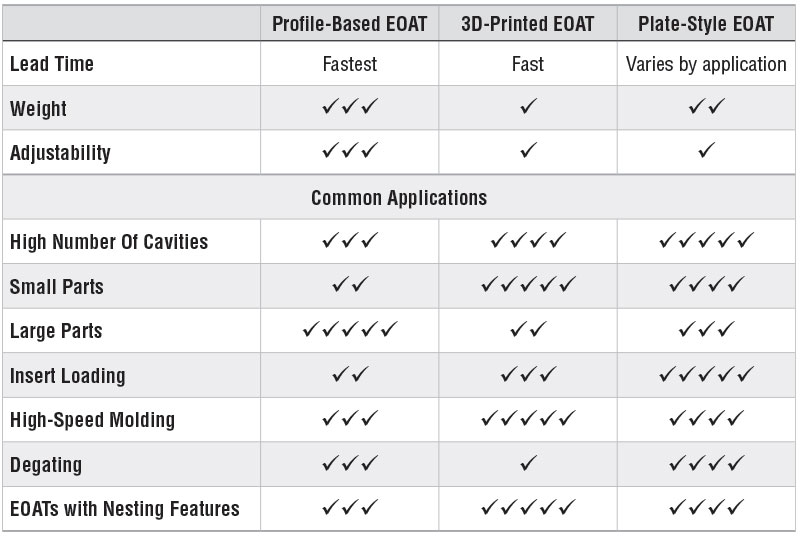

Comparing EOAT Structures

Profile Based EOAT are a proven solution for industrial applications. As you start to expand, weight adds up but the adjustability only increases. EMI has all the needed components in-stock to build adjustable EOAT that can also include 3D printed components for a more custom approach to your application.

EMI’s 3DV Gripper Kit for Cobots is the perfect example of applications for 3D printed EOAT. Internal porting, built-in clamps and pressed inserts help keep it a lightweight, low-cost solution.

Plate Style EOAT offer the highest precision, with reasonable weight requirements, where in some instances, adjustability can be offered for the less critical features of the application. 3D printed components are a perfect addition to plate tools. Custom laser cut or machined plates do require some manufacturing time, and EMI can help with that as well.

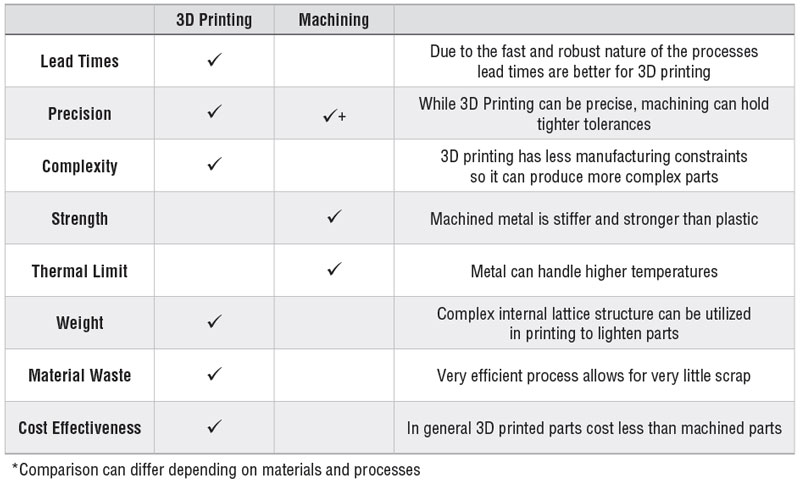

Machined vs. Additive Manufacturing

Our engineers will work with you to develop an optimal product by analyzing your project requirements and time considerations. 3D printing materials have advanced significantly, and the resins we use are well suited to 3D printing gripper fingers and other EOAT components. See our comparison chart below for more information.

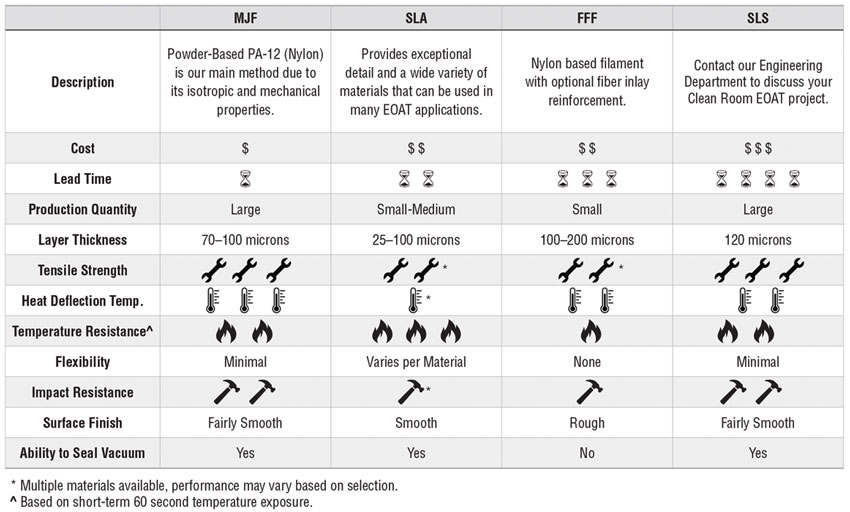

EMI offers four methods of 3D printing for EOAT applications:

The Kit is easy to install and operate. Connect your 6mm compressed air line, a 4-wire cable to the controller box, install our URCap, and your Pneumatic 3D-V Vacuum Kit is ready to expand the capabilities of your Collaborative Industrial Robot.

Features:

- Certified by Universal Robots

- Compatible with OnRobot VGC10

- Fully Customizable: (1–16) vacuum cups with variable spacing.

- Select the ideal vacuum cup for your application: High Temperature, Non-Marking Hithane, Dual Durometer for textured parts, Anti-Static, and many other options. Check out our Vacuum Cup Section.

- Integrated Vacuum Generator with a monitoring switch for part confirmation.

- Internal manifold inside the core of the frame to reduce hazards from tubing.

- Lightweight 3D printed frame made out of durable nylon.

Smaller than the Q# 8210 VG10, the VGC10 can fit into tight environments to extend your automation possibilities. And at half the weight of the VG10 but with the same payload, the VGC10 can lift small, odd-shaped, and heavy objects even with a smaller robot arm. The VGC10 features two independently controlled air channels that allow it to act as a dual gripper with pick-up and release in the same action, further increasing efficiency and reducing cycle time. With no compressor or air supply needed, this compact electrical gripper is easy to move, and simple programming makes it quick and easy to redeploy for greater production flexibility.

- Built-in electric vacuum generator.

- Weight: 0.814kg / 1.79 lbs

- Flexible electric vacuum gripper with unlimited customization fits all your application needs.

- Compact, lightweight gripper is perfect for tight spaces but with plenty of power for objects up to 15kg.

- No external air supply needed.

- Integrated software.

- May require a Compute Box with some Robot models.

| Technical data | |

|---|---|

| Vacuum | 5% — 80% Vacuum (1.5Hg — 24Hg) |

| Air flow | 12 Nl/min (0.42 SCFM) |

| Max. Payload with default attachments* | 6kg (13.2lbs) |

| Max. Payload with custom attachments* | 15kg (33.1lbs) |

| Gripping time | 0.35 seconds |

| Releasing time | 0.20 seconds |

* When using three 40mm cups (more info in the Payload tab to the right). Number of cups needed for non-porous materials varies depending on payload and vacuum.

| Operating Conditions | |

|---|---|

| Power supply | 20.4V — 28.8V |

| Current consumption | 50mA — 1500mA |

| Operating temperature | 32° — 122°F |