S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

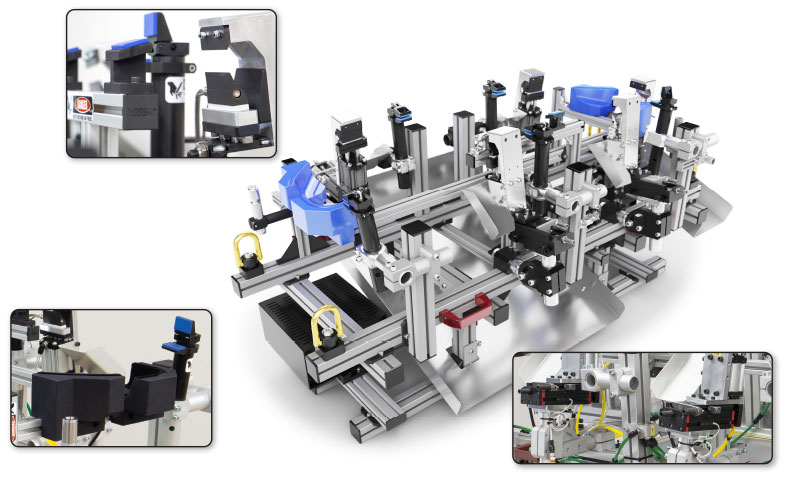

EMI Degate Station Case Study

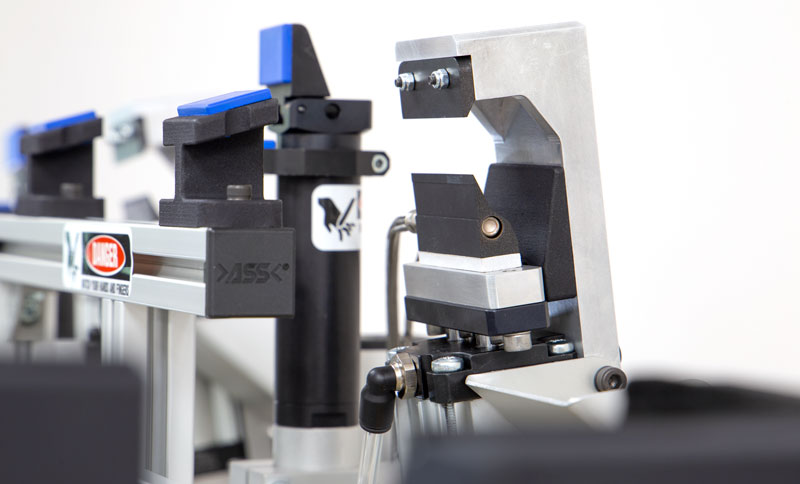

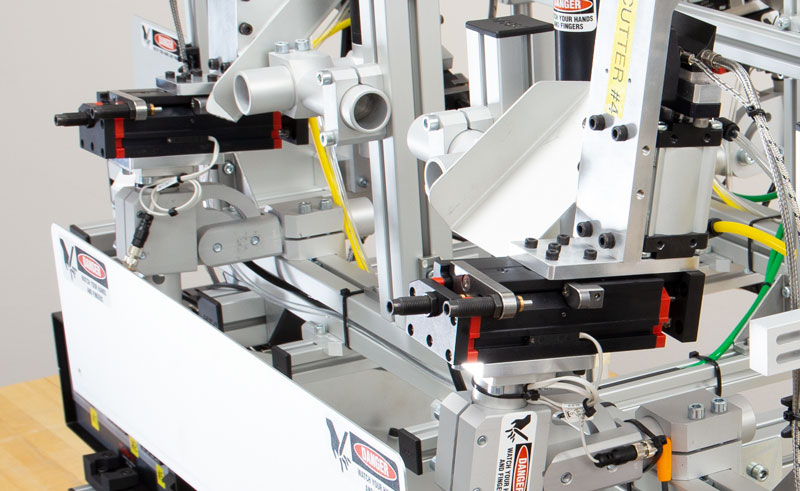

Custom Designed Thrust Cut Nippers

Thrust Cut nippers, available with an optional heat package, are designed to withstand the demands of high volume production. The image below shows a custom thrust cut nipper mounted to a cylinder. Gimatic OFR Gripper Fingers and 3D Printed stops with HNBR pads help secure the part without leaving marks.

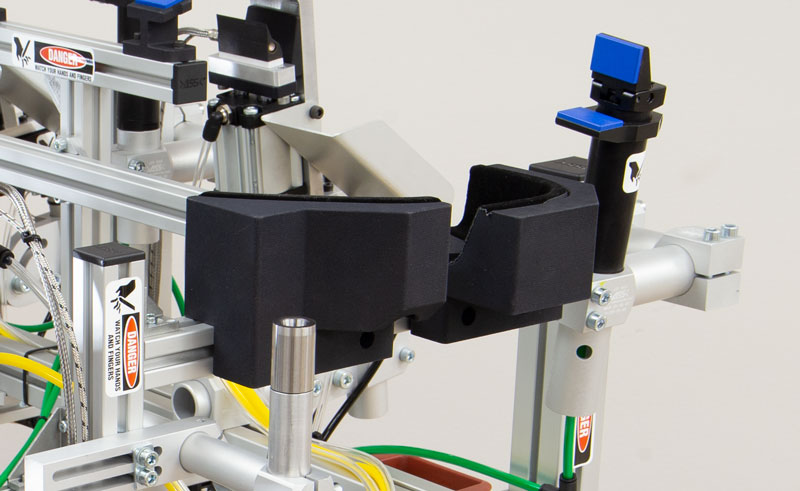

Flocked Parts Nest

In-house 3D Printing allows us to rapidly create custom and cost-effective nests for parts to ensure precise degating. Fiber-lined nests are used here for a soft-touch interface. Find out more about our 3D Printing service.

Integrated Slides

EMI stocks a range of heavy duty, pneumatic linear slide actuators for a wide variety of industrial uses, including End of Arm Tooling. These specific Gimatic Linear Slides feature low profile, high torque, and are especially well-suited for use in the plastics industry. Find out more about the pneumatic slides we offer. Aluminum chutes route sprues out of the way, keeping the area clean ensuring repeatable cuts.

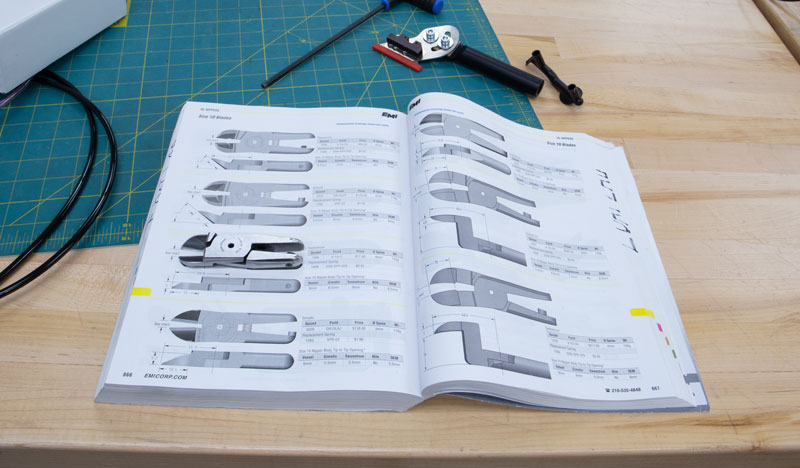

EMI End-of-Arm Tooling Catalog - Nipper Section

EMI has over 100 Nipper blades for both round and square body nippers. Our Nipper Blades are shown at 100% scale so you can work with our catalog on your production line. Request a printed copy of our EOAT catalog today!

EMI End-of-Arm Tooling Catalog - Nipper Section

The nipper section of our catalog includes a wide assortment of nipper bodies and blades, mounting brackets, spare parts, and application examples to guide you. Every part in the catalog links back to our e-commerce so you can easily add items to your cart as you browse.