Web Content Viewer

- ${title}

Specifically engineered to meet the needs of the injection molding industry, EMI Ring Valves meet or exceed OEM specifications.

100% certified steels, 100% inspected valves that exceed OEM specifications. | On-site and phone technical support. | Guaranteed dimensions and hardness specifications.

Check Online Pricing | Ring Valve Order/Quote Form | Valve Material DescriptionsFree Flow Ring Valve

This is the only true 100% free-flow ring valve!

The first 100% free-flow ring valve for shear sensitive materials.

Generous, self-cleaning flow paths minimize residence time, provide excellent screw recovery rates and allow color changes to be made easily. Highly polished radiused surfaces and an exceptionally non-compressive design make it an excellent choice when running shear, compression-sensitive, or fiber filled materials.

Standard: H-13 tool steel, nitrided.

Optional: 440C stainless steel, CPM® 9V® tool steel, CPM S90V® stainless steel.

Control Flow Ring Valve

Excellent all around valve.

Excellent shut-off capabilities and a compression ratio of approximately 2:1, provide outstanding performance for over 90% of all material applications. Smooth, wide flow patterns and low compression allows shear sensitive materials to be run with ease.

Standard: H-13 tool steel, nitrided.

Optional: 440C stainless steel, CPM® 9V® tool steel, CPM S90V® stainless steel.

When independently tested against five other best selling ring valves, the Control Flow valve tested at the top in almost all of the categories tested. Especially outstanding was the cushion position test with less than .003 inches of deviation.

Four-Piece Ring Valves

The most reliable and highest quality four-piece valve available.

#1 in Cushion consistency...Plastics Product Review

#1 in Integral-cavity pressure consistency

#1 in Fill time consistency

#2 in Plastication time consistency

Five generous flow paths for the melt minimize the risk of shear burning. If the check ring’s front seat begins to wear, that’s all you have to replace...you’re back up and running fast without replacing the whole assembly. For general purpose resins, some engineered and fiber-filled materials. Good screw recovery rates, fast shut off and four times the seating area of a ball check, resulting in more positive seating force.

Standard: H-13 tool steel, nitrided.

Optional: 440C stainless steel, CPM® 9V® tool steel, CPM S90V® stainless steel.

Interlocking Ring Valves

EMI’s Interlocking check ring valve is a great design choice for general-purpose material applications. Self-cleaning flow paths provide for quick material changes and the ring rotates with the valve body to aid in reduction of any possible flute wear during processing.

Standard: H-13 tool steel, nitrided.

Optional: 440C stainless steel, CPM® 9V® tool steel, CPM S90V® stainless steel.

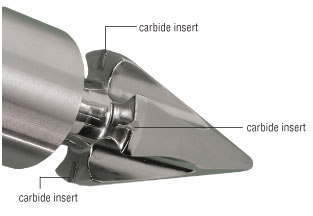

Carbide Inserts

Extended life Carbide Insert valves provide many profit boosting benefits.

Three-piece, four-fluted Carbide Insert valves are made of H-13 and features carbide inserts at the base of each flute. Inserts protrude slightly from the flute allowing the inserts to ride against the ring rather than the flute itself - this has proven to be extremely effective in preventing wear in this area (95% of all valve wear is usually seen in the flute area).

Note: Carbide inserts protect only the flute area, however, adhesion wear (gauling) throughout the valve is usually very minor, resulting in less than 5% of valve replacement.

S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Products Dropdown

- ${title}