S2K Commerce - Products Dropdown

- ${title}

Web Content Viewer

- ${title}

GIMATIC VACUUM THEORY

THE HIGHER THE VACUUM LEVEL, THE GREATER THE ENERGY REQUIREMENT WILL BE:

When vacuum is created inside a suction cup that rests on a surface, the suction cup adheres to the surface not just on its own account, but also thanks to the higher external pressure.

The lifting force is proportional to the contact surface and the vacuum level.

If the vacuum level increases from 60% to 90%, the lifting force increases by a maximum of 1.5 times.

In order to limit the energy consumption, it is preferable to limit the vacuum level and instead increase the surface area of the suction cup.

SURFACE AND STRUCTURE:

As well as highlighting the object's dimensions, a visual assessment identifies wheter the object is curved or flat.

Using the suction cup that best fits the surface is essential.

A further contribution could come from the analysis of the structure of the object.

A more careful examination could reveal a certain roughness which, in addition to limiting the use of suction cups, represents a potential leak.

POROSITY:

What is the porosity of the material?

This question is very important for the definition of the suction cup format and for the sizing of the pump.

Porosity is defined as the amount of air at atmospheric pressure passing through a material subjected to a depression.

Glass does not allow air to pass through, while paper, for example, is full of tiny pores.

MATERIAL:

It is often necessary to check the operating temperature required to perform that particular application.

Too high temperatures, as in thermoforming, or too low, require the use of suction cups made with special compounds.

Silicone is the best solution even if there is a risk of releasing small particles (halo), which makes it difficult to perform a subsequent painting.

In this case our HNBR suction cups are the ideal solution.

SELECTION OF THE SUCTION CUP:

Once the weight and size of the object have been determined, the type and diameter of the suction cup must be determined.

The use of the largest possible suction cup allows to reducethe vacuum level.

This solution offers a number of advantages including shorter evacuation time, reduced power consumption and longer suction cup life.

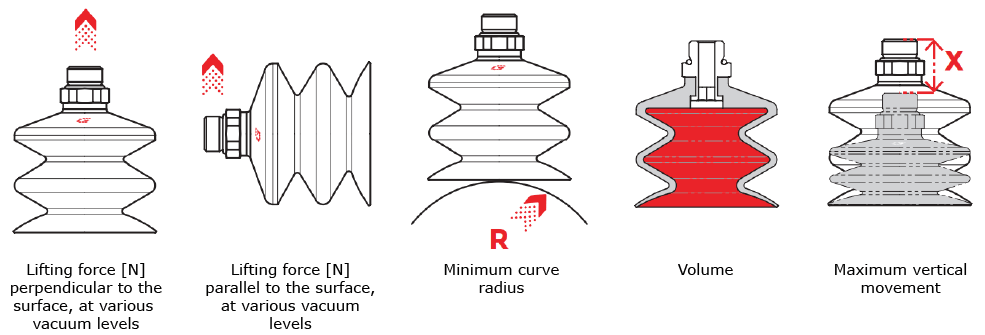

PARAMETERS:

Lifting force [N] perpendicular to the surface, at various vacuum levels

USEFUL PARAMETERS TO VERIFY:

- Use the suction cup that is suitable for the application.

- Pay attention to the type of material and the structure of the surface

- Determine the type of suction cup material suitable for the application.

- Design the system with a suitable safety factor.

- Know the possible dynamic forces that could influence the application.

- Distribute the suction cups in relation to the center of gravity

- Use the appropriate accessories for the application

- Consider the type of finish of the surface.

Quick Links

- Gimatic Vacuum Theory (pdf)

- Go to Gimatic Online Interactive Catalog with links to e-commerce

S2K Commerce - Shopping Cart

- ${title}