Web Content Viewer

- ${title}

GIMATIC GRIPPING SYSTEMS

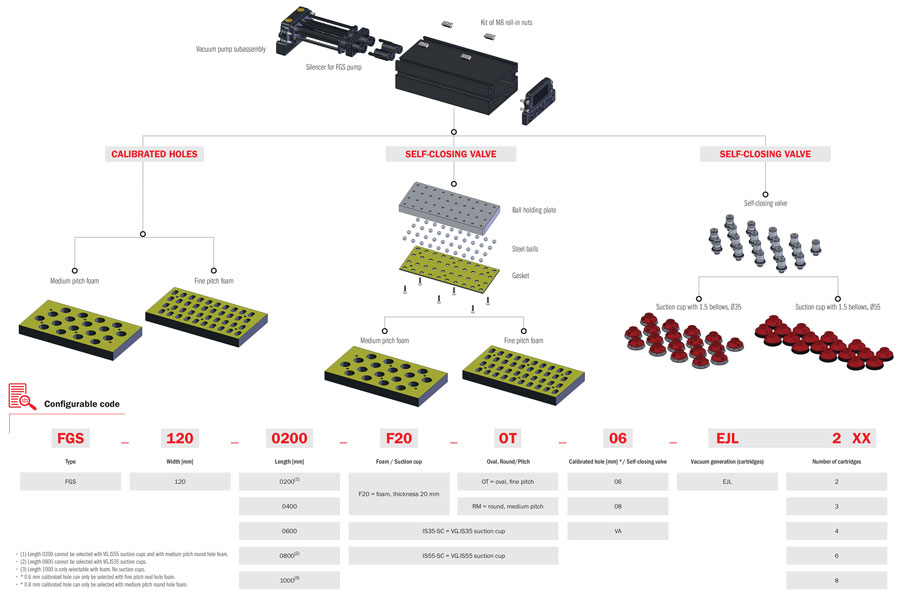

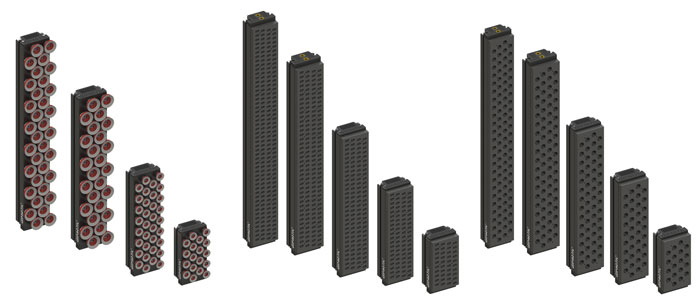

Gimatic FGS-60 foam vacuum gripping systems (60mm),FGS-120 foam vacuum gripping systems (120mm), FGS-120-SC vacuum cup gripping systems (120mm), and the Foam Gripper with Carbon Fiber Body are all equipped with an integrated vacuum generator and are available with self-closing valves or with calibrated holes.

The integrated vacuum generator consists of EJ-LARGE-HF-3 multistage ejectors. These ejectors have high suction capacity, low energy consumption, no moving mechanical parts, and do not generate heat.

- Available with foam or with VG.IS polyurethane suction cups.

- Foam gripper width is either 60mm or 120mm, and available in multiple lengths: 200mm, 400mm, 600mm, 800mm, 1000mm, and 1200mm. Custom sizes available, contact EMI.

- Available in different hole pitches as required.

TYPICAL APPLICATIONS:

Palletizing and handling applications in different industries. Ideal for handling cardboard boxes, wooden panels, cans and many other products with different formats and shapes.

FOAM FEATURES:

- Material: EPDM

- Thickness: 20mm

- Temperature range: -40°F — 275°F (-40°C — 135°C)

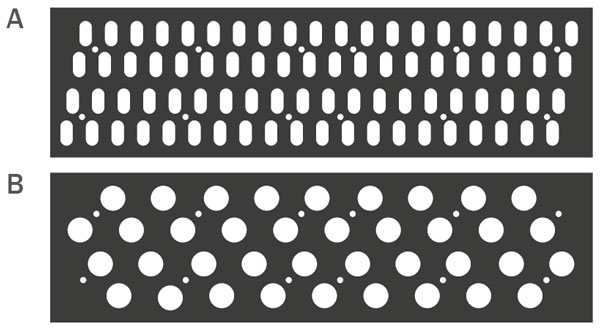

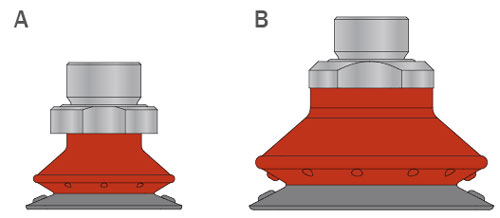

- Fine pitch oval (A) for objects with a minimum width of 35mm.

- Medium pitch round (B) for objects with a minimum width of 55mm.

- Easy to install and remove with no residue on the extruded piece.

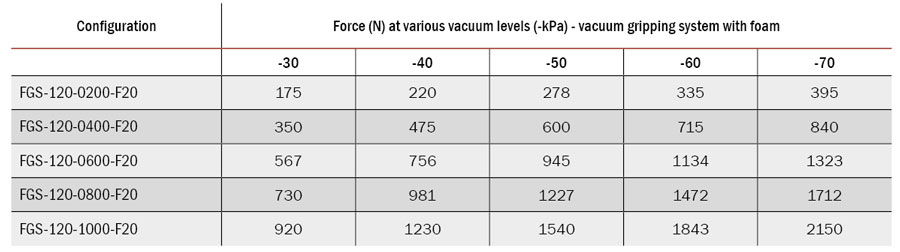

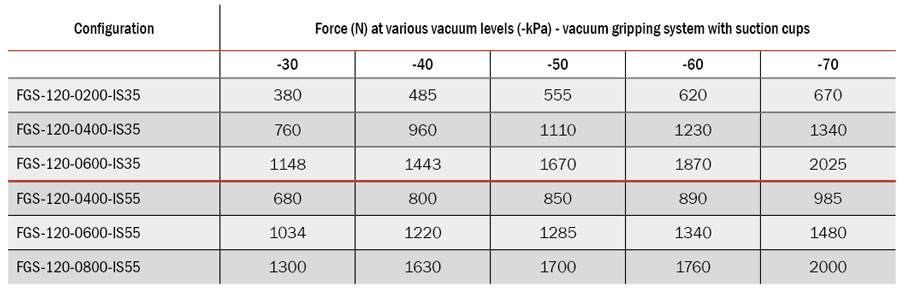

LIFTING FORCE: Theoretical gripping force on flat surface, with fully covered gripping surface, safety factor (N) excluded.

SUCTION CUP FEATURES:

- Material: Polyurethane (PU)

- Temperature range: 32°F — 122°F (0°C — 50°C)

- Available sizes: 35mm cup: VG.IS35 (A), and 55mm cup: VG.IS55 (B).

- The VG.IS polyurethane suction cups ensure high wear resistance and adaptability to uneven and porous surfaces.

LIFTING FORCE: Theoretical gripping force on flat surface, with fully covered gripping surface, safety factor (N) excluded.

OPERATING PRINCIPLE FOR SELF CLOSING VALVES:

How it works: The vacuum channel has a chamber containing a metal ball. In the absence of the object to be picked up, the metal ball moves and hermetically closes the vacuum channel.

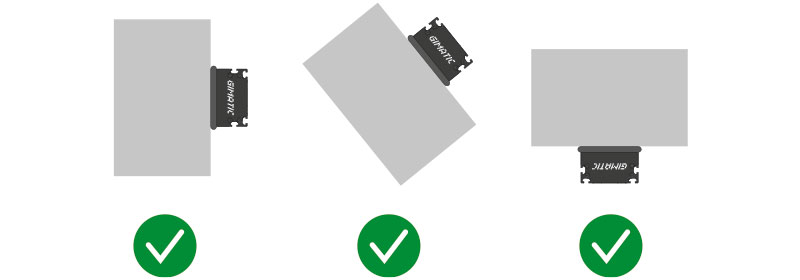

When to use it: Ideal in different applications and formats, where a high level of vacuum must be maintained, despite the fact that most of the surface of the manipulator may not be gripping.

Strengths: Faster, more flexible, less sensitive to dust, with lower consumption as it requires smaller pumps.

- Positioning of the gripping system on the object to be handled, parallel to the gripping surface.

- Approaching of the gripping system until contact is made with the gripping surface.

- Activation of vacuum generation.

- Picking up of the object to be handled.

- Deposit of the object with vacuum deactivation and blow-off if necessary.

OPERATING PRINCIPLE FOR CALIBRATED HOLES:

How it works: The vacuum channel has a bottleneck (calibrated microhole), which generates a known leak in the vacuum chamber if the object to be picked up is missing.

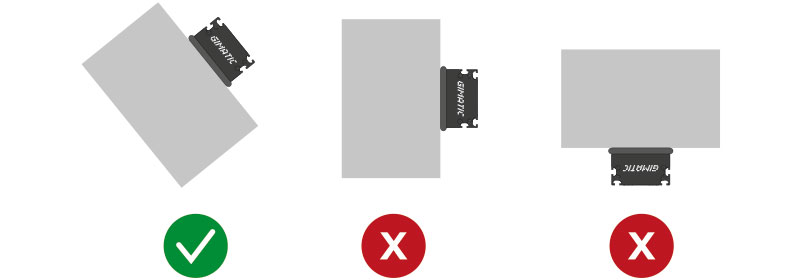

When to use it: Ideal when self-closing valves cannot be used (e.g. in vertical handling applications) or when the gripping system covers about 90% of the gripping surface to be handled.

Strengths: Can also work at 180°, lightweight.

- Positioning of the gripping system on the object to be handled, parallel to the gripping surface.

- Approaching of the gripping system until contact is made with the gripping surface. Vacuum activation before contact with the object is advised for high-speed applications.

- Picking up of the object to be handled.

- Deposit of the object with vacuum deactivation and blow-off if necessary.

EXPLODED VIEW:

Click image for larger view

Quick Links

- Gimatic Foam Gripper Brochure (pdf)

- Go to Gimatic Foam Grippers

- Go to Gimatic Online Interactive Catalog with links to e-commerce

S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}